In today’s fast-paced global economy, businesses face pressure to deliver goods quickly. They also need to cut costs and boost customer satisfaction. Traditional warehousing models – where products sit in storage for days or weeks – are no longer always efficient. This is where cross docking in logistics plays a vital role.

It is a smart logistics method. It reduces storage time, speeds up delivery, and improves supply chain efficiency.

In this blog, we will explain cross docking. We will discuss how it works, its benefits, and its challenges. We will also cover why it is important in today’s logistics and supply chain operations.

Cross Docking Meaning: A Simple Explanation

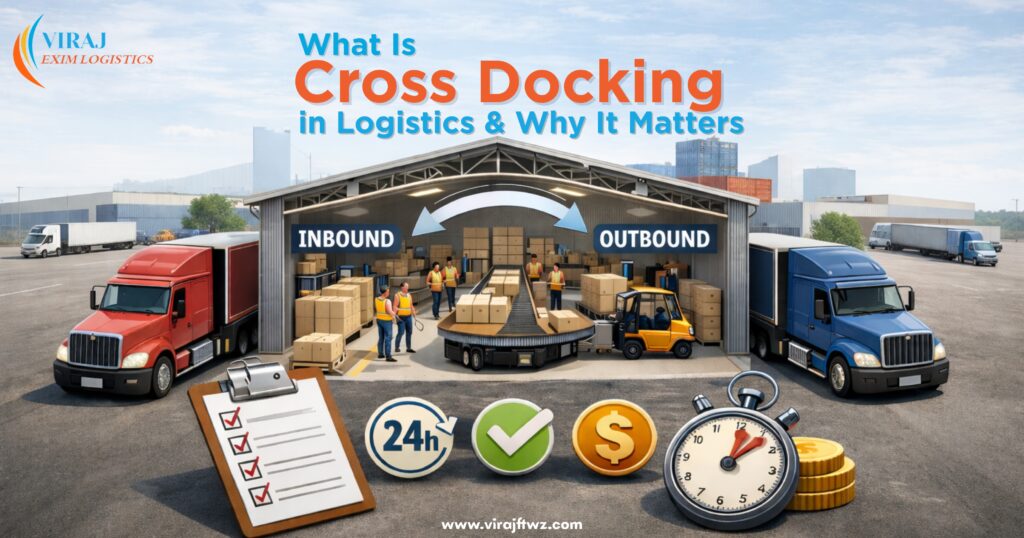

Cross docking is a logistics practice. It involves unloading products from incoming transport.

These products are then quickly moved to outgoing vehicles. There is little or no storage time in between. Instead of placing goods in a warehouse, workers “cross” the dock from receiving to shipping.

In simple terms, it eliminates the need for long-term warehousing. Products arrive, are sorted or consolidated if necessary, and then quickly shipped to their next destination.

What Is Cross Docking and How Does It Work?

It involves a streamlined flow of goods through a distribution facility. The process typically includes:

1. Inbound freight arrival

Goods arrive at a cross docking facility from suppliers or manufacturers.

2. Freight handling and sorting

Products are inspected, labeled, and sorted according to destination.

3. Minimal or no storage

Items are not stored in racks or shelves. Instead, they remain on the dock floor for a short period.

4. Outbound shipment

Goods are loaded onto outbound trucks and shipped to retailers, distributors, or customers.

This process requires precise coordination, real-time information, and reliable transportation networks to work efficiently.

Read more: Inbound Logistics: Key Processes, Advantages, and Best Practices

Cross Docking in Logistics: Why It’s Gaining Popularity

It has gained popularity because it addresses many of the limitations of traditional warehousing. With rising fuel costs, increased customer expectations, and the growth of e-commerce, logistics providers need faster and leaner systems.

It allows companies to:

- Reduce handling time

- Minimize storage costs

- Speed up delivery cycles

- Improve accuracy in shipments

Industries such as retail, FMCG, automotive, pharmaceuticals, and food distribution often use cross-docking. This helps them move goods quickly.

Types of Cross Docking in the Supply Chain

1. Pre-Distribution Cross Docking

Products are sorted and labeled before arriving at the dock. Once they reach the facility, they are immediately transferred to outbound trucks.

2. Post-Distribution Cross Docking

Goods arrive unsorted. Sorting and allocation happen at the cross dock facility before final shipment.

3. Continuous Cross Docking

Used for high-volume operations where products continuously flow from inbound to outbound transportation without interruption.

Each type is chosen based on business needs, shipment volumes, and delivery timelines.

Key Benefits

It offers several operational and financial advantages for businesses and logistics providers.

1. Improved Supply Chain Efficiency

By reducing storage and handling time, it significantly enhances supply chain efficiency. Faster movement of goods leads to quicker order fulfillment and happier customers.

2. Lower Warehousing Costs

Since products spend minimal time in storage, businesses save on warehousing space, labor, and inventory carrying costs.

3. Faster Delivery Times

It helps goods move quickly from suppliers to end users. This is important in today’s market, which is driven by demand.

4. Reduced Risk of Damage

Less handling and storage reduce the risk of product damage, loss, or theft.

5. Better Inventory Management

Cross docking supports efficient inventory management by reducing excess stock and preventing over-inventory situations.

Role of Freight Handling in Cross Docking

Effective freight handling is the backbone of successful cross docking operations. Since goods move quickly through the facility, there is little margin for error.

Key aspects of freight handling include:

- Accurate labeling and documentation

- Real-time tracking of shipments

- Skilled labor for quick loading and unloading

- Use of automated systems where possible

Efficient freight handling ensures that shipments reach the correct destination without delays or misrouting.

Cross Docking vs Traditional Warehousing

To understand the value of cross docking, it helps to compare it with traditional warehousing.

Traditional warehousing is still important for some industries. However, cross docking is better for fast-moving and time-sensitive goods.

Challenges of Cross Docking in Logistics

1. High Dependency on Coordination

Any delay in inbound shipments can disrupt the entire operation.

2. Technology Requirements

Accurate tracking systems and real-time data are essential for smooth execution.

3. Limited Error Tolerance

Since goods move quickly, errors in sorting or labeling can lead to misdeliveries.

4. Not Suitable for All Products

Fragile, customized, or low-volume items may not be ideal for cross docking.

Understanding these challenges helps businesses decide whether cross docking fits their logistics strategy.

When Should Businesses Use Cross Docking?

It is most effective when:

- Demand is predictable

- Products have a high turnover rate

- Delivery speed is critical

- Inventory holding costs are high

Retailers, wholesalers, and manufacturers looking to optimize operations often adopt cross docking as part of their logistics model.

The Future of Cross Docking in Supply Chains

As supply chains become more digital and customer-centric, it will continue to evolve. Advanced technologies such as warehouse automation, AI-based demand forecasting, and real-time shipment tracking will improve cross-docking efficiency.

With growing emphasis on sustainability, reducing storage space and unnecessary transportation also makes cross-docking an environmentally friendly logistics solution.

About Viraj Exim Logistics

When you need reliable and efficient logistics in India, Viraj Exim Logistics is a trusted name. Viraj Exim Logistics has years of industry experience. We provide freight forwarding, transportation, and supply chain solutions. Our services are designed to meet the needs of today’s businesses.

The company focuses on efficiency, transparency, and customer satisfaction, ensuring smooth freight movement across domestic and international routes. Viraj Exim Logistics uses smart logistics strategies, strong infrastructure, and a dedicated team. This helps businesses improve operations and lower costs.

Viraj Exim Logistics is one of the top logistics companies in India. We offer many services to help with fast, secure, and scalable supply chain operations. Whether it’s freight handling, transportation management, or end-to-end logistics solutions, the company is committed to delivering excellence at every step.

Final Thoughts

Cross-docking in logistics is not just a trend. It is a smart way for businesses to move faster, work more efficiently, and stay competitive in a changing market. It is essential in today’s distribution networks. It helps reduce storage time, improve inventory management, and make supply chains more efficient.

With good planning, technology, and a logistics partner, it can be a strong tool for long-term business success.

Reference

Cross-docking by Wikipedia[1].